Committing Cargo Quantities in Tanker Ships

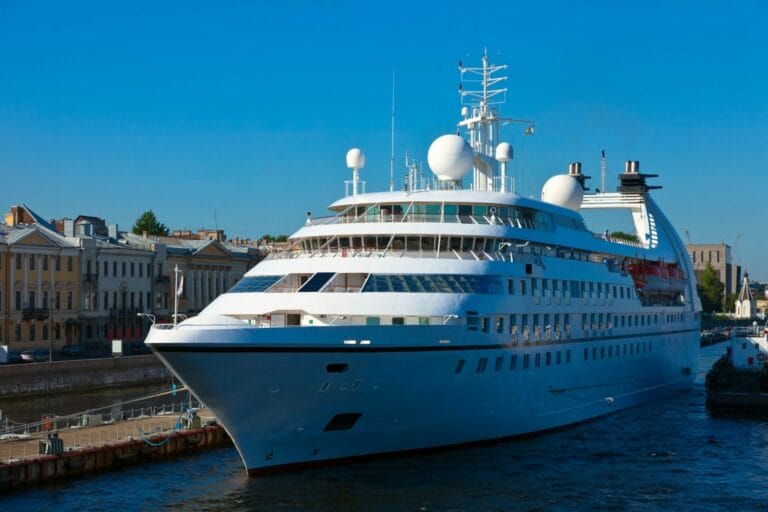

Ensuring the safe and efficient loading and unloading of cargo is a crucial aspect of tanker shipping, with utmost consideration for the marine environment.

Loading and unloading cargo safely involves thorough pre-planning before determining the nominated quantity and making fixture arrangements. It encompasses evaluating the cargo’s compliance with company requirements, assessing the ship’s damage stability conditions and minimum stability requirements for tankers, and checking load line zones for maximum loadable quantity, especially when sailing through different zones.

Efficiency in cargo operations aims to minimize or eliminate any remaining cargo onboard (ROB) after discharge and emphasizes optimal loading and unloading procedures within the vessel and terminal limits, while maintaining safety standards.

Environmental protection is of utmost importance due to the potential discharge of large quantities of oil and chemicals, whether caused by accidental spills or human errors. Such incidents can disrupt the marine ecosystem and lead to adverse effects of pollution.

Preparation

Cargo pre-loading preparation involves various considerations:

- Compliance: The maximum cargo quantity to be loaded should align with company requirements.

- Stability: The cargo quantity should be evaluated based on the ship’s stability conditions and compliance with tanker stability requirements.

- Voyage Instructions: Thoroughly review the nominated cargo’s details, including quantity, quality, carriage, and discharge. Request any missing relevant information from the charterers.

- Segregation: Ensure the vessel can maintain segregation requirements for different cargo grades and vapor segregation, as instructed by the charterers.

- Tank Suitability: Verify that cargo tanks meet the requirements for carrying specific types, grades, and nature of cargo. Tank coating and material compatibility play a crucial role in determining suitability.

- Tank Preparation: Ensure all cargo tanks and lines are thoroughly cleaned and free from remains of previous cargoes or wash water. Certain cargoes, like jet fuel, can be contaminated by water, leading to rejection during loading.

- Heating Requirements: If certain cargoes require heating, carefully review instructions provided by charterers to comply throughout the voyage and ensure efficient discharge.

- Recordkeeping: Maintain records of tank temperatures, both upper and lower regions, along with daily ambient air and sea temperatures, especially when cargo heating is necessary during the voyage.

- Crude Oil Washing (COW): Check cargo suitability for COW and consider terminal requirements.

- Density Considerations: Check cargo density and examine maximum allowable tank capacities to avoid exceeding weight limits.

- Ullage Determination: Consider air and sea water temperatures, as they affect cargo volume changes inside tanks, especially when loading above 95%.

Each cargo type and chemical nature has its own specific handling requirements and precautions. These points serve as a general guideline to ensure hassle-free and safe loading, carriage, and discharge of cargo while minimizing delays and potential claims.

Note: The real-life incidences mentioned highlight the importance of proper tank cleaning, stripping, and adherence to cargo specifications to avoid cargo rejection and associated consequences.

Need Help At Sea ? Contact Us Now!

BALANCIA SHIP AGENCY

HQ Address : Komplex Ruko Golden City Block C No.3A, Batam City, Indonesia 29432

www.balancia.co.id

Mobile Ph. : +628112929654

Office Ph. : +627784883769