10 Situations When Ship Generator Must be Stopped Immediately

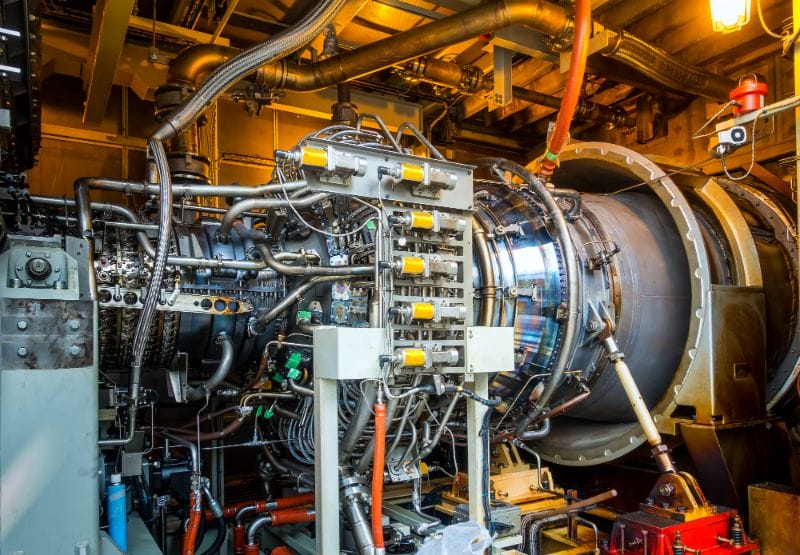

The ship generator serves as the powerhouse, providing essential electrical power for various systems and machinery. To ensure efficient and safe operations, regular maintenance and overhauling of the generator are imperative. A responsible marine engineer understands the significance of proactive measures to prevent machinery breakdown or failure in the engine room. Waiting until the generator is on the verge of a breakdown is never an option. Instead, taking all necessary precautions to avert impending troubles arising from engine room machinery failures or breakdowns is paramount.

The early stages of a problem in the generator are often characterized by subtle indications that a major issue may be looming. Assessing this critical situation requires the expertise of a ship’s engineer, who must be able to discern the signs and take prompt action. Unfortunately, instances arise every year where auxiliary engine breakdown occurs despite multiple indications, forewarning the unfortunate outcome.

Outlined below are ten critical scenarios wherein immediate action is necessary: starting the standby engine and stopping the auxiliary engine experiencing trouble, thereby preventing a dangerous situation from evolving into a major disaster:

Abnormal or Queer Sound

The ship generator engine comprises intricate, heavy oscillating and moving parts. Additionally, attached auxiliaries such as turbochargers and pumps are high-speed machines that generate a significant amount of sound. Any abnormal sound, regardless of its faintness, should never be dismissed. When an unusual sound is detected, the engine must be promptly shut down, followed by troubleshooting to identify and rectify the issue.

Smoke

The sight of smoke emanating from the generator or its vicinity signifies a critical stage where immediate action is imperative. Halting the generator without offloading it is necessary, as the situation has already escalated beyond the danger threshold. The emergency stop button provided in a local or remote station should be utilized. Smoke may result from friction between moving parts, overheating, or other factors that demand immediate attention.

Unusual Lubricating Oil Parameters

In cases where the lubricating oil temperature exceeds normal limits or the oil pressure drops below the adequate level, the generator must be promptly stopped. Identifying the underlying cause, such as a dirty lube oil cooler or a clogged filter, is essential for troubleshooting and rectification.

Higher Differential Pressure

Differential pressure serves as an indicator of the lube oil filter’s condition. It involves measuring the pressure before and after the filter, with the difference displayed on a gauge. If the differential pressure reading falls within a higher range, it signifies a potential issue, requiring the generator to be stopped and the standby filter to be activated.

Overspeed

The generator operates at high speeds, making over-speeding a significant hazard that can result in explosions and casualties. Over-speeding often arises from fuel system problems, particularly governor malfunctions. If the generator continues to run above its rated speed without tripping, immediate generator shutdown is necessary to prevent a major accident. Subsequent crankcase inspection and renewal of bottom end bolts become essential procedures.

Cooling Water Supply

Adequate cooling water supply is crucial for maintaining the smooth operation of high-temperature moving parts within the generator. If the cooling water supply fails due to pump malfunctions, the generator must be stopped immediately to prevent overheating and subsequent damage.

Leakage from Pipings

Any leakage observed from fuel, lube oil, or cooling water pipes necessitates the generator’s immediate shutdown. This allows engineers to address the leakage effectively, ensuring proper maintenance and repairs.

Vibration and Loose Parts

Vibration is a leading cause of increased wear on moving parts. If loose bolts or heavy vibration are detected while the engine is running, the generator must be stopped promptly to investigate and rectify the underlying causes.

Non-functional Alarms and Trips

If any alarms or trips associated with the running generator are found to be non-functional, immediate generator shutdown is essential. This proactive measure prevents potential failures in the event of an accident, ensuring the safety of the generator and its surroundings.

Water in Oil

The presence of water in the generator’s oil decreases its load-carrying capacity, potentially leading to bearing damage. When a significant amount of water is detected, the generator should be stopped promptly. Identifying the source of the leakage and purifying or renewing the sump oil becomes crucial before returning the generator to operation.

In all of these scenarios, swift and decisive action is critical for mitigating risks and preventing further damage. Regular inspections, meticulous adherence to maintenance procedures, and a proactive approach are fundamental to ensuring the safe and reliable operation of the ship’s generator engine.

Need Help At Sea ? Contac Us Now!

BALANCIA SHIP AGENCY

HQ Address : Komplex Ruko Golden City Block C No.3A, Batam City, Indonesia 29432

www.balancia.co.id

Mobile Ph. : +628112929654

Office Ph. : +627784883769